The cosmos has always beckoned humanity with its siren call of infinite possibilities, but bridging the void between stars demands more than just courage—it requires the alchemy of fire and metal. Welding the Galaxy: The Spark Oath of High-Temperature Fusion isn’t merely a poetic turn of phrase; it’s a manifesto for the next era of interstellar engineering. Across research labs and orbital shipyards, a quiet revolution is unfolding, one where the art of welding transcends terrestrial limits to stitch together the fabric of deep space.

At the heart of this movement lies an unshakable truth: the vacuum of space is no friend to traditional construction. Zero gravity, cosmic radiation, and extreme thermal fluctuations render Earth-bound techniques obsolete. Here, conventional welds crack under the strain, and adhesives vaporize into the void. The solution? A new generation of high-temperature fusion welding, where plasma arcs and electron beams replace torches, and the very act of joining metal becomes a cosmic covenant.

The Crucible of Innovation

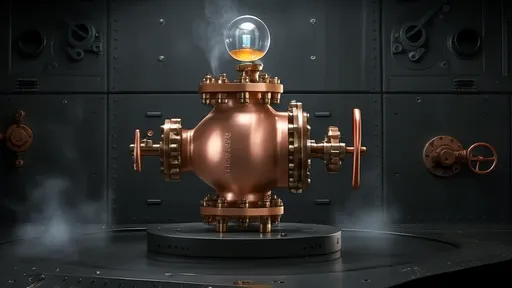

NASA’s Advanced Materials Lab recently unveiled a prototype welder capable of operating at 3,000 degrees Celsius in microgravity—a feat once deemed impossible. The device, dubbed "Vulcan’s Needle," uses magnetic fields to stabilize molten metal droplets mid-fusion, allowing for precision joins in the absence of atmospheric pressure. Meanwhile, private ventures like StarForge Dynamics are pioneering laser-assisted friction-stir welding, where overlapping atomic lattices are literally stirred together at sub-molecular levels. The result? Seams stronger than the parent material itself.

Yet the true breakthrough lies in the metallurgy. Alloys infused with carbon nanotubes and self-healing ceramic matrices are rewriting the rules of durability. When a weld on the lunar surface is bombarded by micrometeorites, these materials don’t just withstand impact—they reconfigure their crystalline structures to seal fractures autonomously. It’s as if the welds possess a biological imperative to survive.

The Human Element

Behind every stellar weld burns an equally intense human drama. Take Dr. Elara Voss, lead engineer on the Mars Orbital Dock project, who spent 17 months perfecting a zero-g welding protocol only to watch her first test sample float away into the void. "That moment taught me that space isn’t just an environment," she reflects. "It’s an active participant—sometimes an adversary." Her team’s subsequent breakthrough, using ultrasonic vibrations to "herd" molten metal into place, has since become standard practice across the industry.

Then there are the orbital welders themselves—men and women who train underwater for years to simulate spacewalks, their every movement choreographed to conserve oxygen while manipulating searing-hot tools. Their lexicon has evolved too: phrases like "dancing the arc" (maintaining perfect torch alignment during a spacewalk) or "singing the seam" (detecting weld integrity through harmonic resonance) hint at the artistry hidden within this brutal science.

The Covenant of Fire

Perhaps what’s most striking is how ancient this new technology feels. When a welder on the International Space Station’s expansion module strikes an arc, the resulting light show—a miniature supernova contained within their visor—echoes humanity’s first mastery of fire. The same primal awe persists, now harnessed to build bridges between worlds. Every perfect weld becomes a votive offering to progress, a promise etched in molten steel that we will not be bound by terrestrial limits.

As the first structural beams for the Lunar Gateway station are fused in orbit this year, each spark will carry the weight of that oath. For in the grand tapestry of cosmic expansion, it’s not the rockets or AI that will bind the galaxy together—it’s the welders, their tools glowing like captured stars, writing our future in streaks of liquid metal across the darkness.

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025