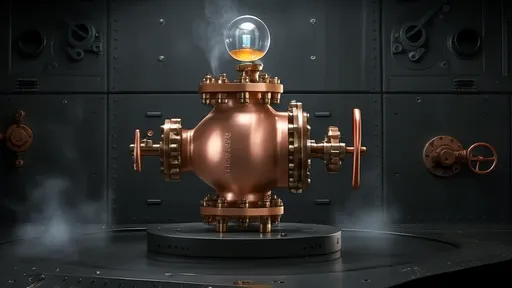

In the heart of every machine, hidden beneath layers of grease and metal, lies an unsung hero—the humble bearing. Its dance is one of precision, a silent symphony of steel spheres gliding effortlessly in their tracks. This is not just mechanics; it is artistry in motion, a ballet of physics and engineering that keeps the modern world turning.

The bearing’s elegance lies in its simplicity. A carefully crafted ring, a set of polished steel balls, and a cage to guide them—these are the components that transform friction into fluidity. When in motion, the steel spheres roll with a rhythm so perfect it seems almost musical. Each rotation is a note, each revolution a stanza in an unending song of efficiency.

What makes this dance so mesmerizing is the interplay between force and freedom. The bearing does not resist motion; it embraces it. The steel balls distribute weight evenly, reducing friction to a whisper. This is why machinery equipped with high-quality bearings operates with such seamless grace—whether in the whirring of an electric fan or the roaring spin of a jet engine.

The Science Behind the Spin

Behind the poetic motion of bearings lies a foundation of rigorous science. The geometry of the balls, the smoothness of the raceways, and the precision of the cage all contribute to the bearing’s performance. Even the slightest imperfection—a microscopic scratch or a minuscule deviation in roundness—can disrupt the harmony, leading to increased wear or catastrophic failure.

Engineers and metallurgists spend lifetimes perfecting these components. The steel must be hardened to resist deformation, yet retain enough toughness to withstand shock loads. The surfaces are ground and polished to near-mirror finishes, ensuring that contact between the balls and raceways is as smooth as ice on glass. Lubricants, whether grease or oil, are chosen with care, their viscosity tailored to the bearing’s operating conditions.

This meticulous attention to detail is what allows bearings to perform under extreme conditions. From the freezing vacuum of space to the scorching heat of industrial furnaces, bearings adapt and endure. They are the silent sentinels of motion, enabling everything from the delicate movements of a wristwatch to the thunderous power of a freight train.

The Unsung Hero of Modern Industry

Bearings are everywhere, yet they are rarely noticed—until they fail. A single faulty bearing can bring an entire production line to a halt, or worse, cause a catastrophic accident. This is why industries invest heavily in bearing maintenance and monitoring. Vibration analysis, thermal imaging, and acoustic testing are just a few of the tools used to ensure these critical components remain in perfect health.

In aerospace, bearings must meet standards so stringent that even a speck of dust can disqualify them. Medical devices rely on ultra-clean, ultra-precise bearings to ensure smooth operation in life-saving equipment. Even in everyday appliances, the quality of the bearings determines longevity and performance. A washing machine that lasts a decade does so because of its bearings.

Yet, for all their importance, bearings rarely receive the recognition they deserve. They are the invisible enablers, the quiet facilitators of progress. Without them, the wheels of industry would grind to a halt, and the gears of innovation would seize.

The Future of Bearing Technology

As technology advances, so too does the science of bearings. New materials like ceramic hybrids and advanced polymers are pushing the boundaries of what bearings can achieve. Self-lubricating designs and smart bearings embedded with sensors are transforming maintenance from reactive to predictive, saving industries millions in downtime.

Researchers are even exploring magnetic and air bearings, which eliminate physical contact entirely, reducing friction to near-zero. These innovations promise to revolutionize fields from renewable energy to high-speed transportation, where efficiency and reliability are paramount.

Yet, no matter how advanced bearings become, their essence remains the same—a celebration of motion, a testament to humanity’s quest for smoother, faster, better. The ballet of bearings will continue, its rhythm unbroken, its dancers ever-evolving.

In the end, the bearing is more than just a component. It is a symbol of harmony between man and machine, a reminder that even in the cold precision of engineering, there is beauty to be found. The next time you hear the hum of an engine or the spin of a wheel, take a moment to appreciate the steel ballet unfolding within—the fluid, flawless dance of rolling spheres.

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025