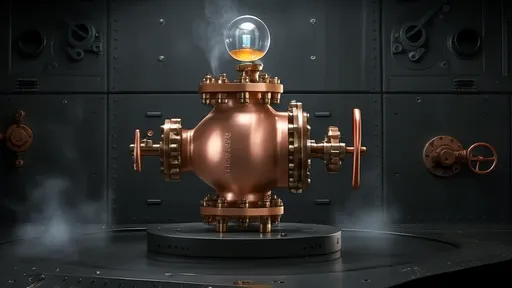

The rhythmic dance of interlocking metal teeth has powered human civilization’s mechanical progress for centuries. Gear meshing, often described as the "precision kiss of metal teeth," is far more than mere mechanical contact—it’s a symphony of physics, engineering, and artistry. From ancient water clocks to Mars rovers, this unassuming yet profound interaction remains the backbone of motion transmission. The perfection of this silent dialogue between gears dictates efficiency, longevity, and even the safety of machinery.

At its core, gear meshing is the transfer of motion and force between two or more gears. The teeth of one gear slide into the valleys of another, creating a seamless transfer of energy. But this simplicity belies an extraordinary complexity. Every micron of tooth profile, every degree of pressure angle, and every surface finish imperfection can amplify into catastrophic failure. Modern gear design isn’t just about geometry; it’s about predicting how metal will behave under stress, heat, and relentless cycles of engagement.

The history of gear meshing is a testament to human ingenuity. Early wooden gears, like those in Archimedes’ mechanisms, relied on crude approximations of tooth profiles. The Industrial Revolution demanded precision, giving rise to standardized tooth forms like the involute curve—a shape that ensures constant velocity ratio even as gears wear. Today, aerospace and automotive industries push boundaries further, with computer-aided tolerance analysis and microscopic surface coatings to minimize friction losses at 10,000 RPM.

Material science plays a starring role in this narrative. Case-hardened steels, powdered metals, and even ceramic composites are engineered to withstand the Hertzian contact stresses—pressures so intense they can momentarily exceed the yield strength of the material. Lubricants, too, have evolved into sophisticated formulations with nano-additives that chemically bond to metal surfaces, reducing wear during the critical "boundary lubrication" phase when gears first engage.

Yet challenges persist. Gear whine, that high-pitched complaint from transmissions, isn’t just an annoyance—it’s evidence of microscopic deviations in tooth alignment. Engineers now use laser interferometry and acoustic emission sensors to detect these issues before assembly. Meanwhile, the quest for silent electric vehicles has exposed new frontiers: without combustion engine noise, even the faintest gear mesh irregularity becomes audible to passengers.

The future of gear meshing lies in paradoxes. How to make gears simultaneously stronger and lighter? How to maintain precision in 3D-printed gears with layered microstructures? Researchers are experimenting with bio-inspired designs, mimicking the interlocking teeth of snake scales or the self-healing properties of bone. Others explore digital twins, where every physical gear has a virtual counterpart that predicts wear in real-time using AI.

In workshops worldwide, the ritual continues—engineers leaning close to listen to the whisper of meshing gears, their trained ears detecting nuances no instrument can yet fully quantify. This marriage of ancestral craftsmanship and quantum-level material science keeps our world in motion. The next time you shift gears in a car or wind a mechanical watch, remember: you’re presiding over a ballet of metal teeth, perfected over millennia, still evolving with every rotation.

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025

By /Aug 18, 2025